Page 5 of 7

Re: Recent projects

Posted: Mon Feb 19, 2024 1:39 pm

by Blast

I was given a billet of wootz steel on Saturday. It's sitting at around 2 percent carbon. It was made using a small induction forge.

Wootz steel days back 2500 years to the Indian Subcontenent.

Made in small batches, it's called crucible steel as its made in sealed crucibles in mud brick furnaces. Western Europe wouldn't develop anything like this until close to the 1800's.

The ancient smith's likely followed recipes like they were cooking when prepping the billets, not realizing that items through in, perhaps the burned bones of an ancestor, or peel off some fruits, added needed metals such as phosphorous and manganese.

The high level of carbon in it will make it a challenge to forge as it actually lowered the melting point of the steel. The carbon also forms carbide crystals that interlock with the iron crystals and strengthen it. Wootz steel was reported to be extremely tough and springy and is being studied in depth.

The maker of my bllet is a chemical engineer and is working with a metallurgist from very big forge in the area that handles making parts that start off with 40000 pound ingots and make parts for the space industry.

I'm going to be doing a picture thread on this one.

Re: Recent projects

Posted: Mon Feb 19, 2024 3:19 pm

by Animal

will you make a knife out of it?

Re: Recent projects

Posted: Mon Feb 19, 2024 8:56 pm

by Blast

Animal wrote: ↑Mon Feb 19, 2024 3:19 pm

will you make a knife out of it?

Yup. That was its primary use, if I remember the secondary use was making mirrors. It's going to take a couple hours to work out down to a billet that I can use.

Re: Recent projects

Posted: Mon Feb 19, 2024 8:59 pm

by Animal

Blast wrote: ↑Mon Feb 19, 2024 8:56 pm

Animal wrote: ↑Mon Feb 19, 2024 3:19 pm

will you make a knife out of it?

Yup. That was its primary use, if I remember the secondary use was making mirrors. It's going to take a couple hours to work out down to a billet that I can use.

have you decided on the shape of the knife you will make? What will it be used for?

Re: Recent projects

Posted: Mon Feb 19, 2024 11:01 pm

by Blast

Animal wrote: ↑Mon Feb 19, 2024 8:59 pm

Blast wrote: ↑Mon Feb 19, 2024 8:56 pm

Animal wrote: ↑Mon Feb 19, 2024 3:19 pm

will you make a knife out of it?

Yup. That was its primary use, if I remember the secondary use was making mirrors. It's going to take a couple hours to work out down to a billet that I can use.

have you decided on the shape of the knife you will make? What will it be used for?

Leaning towards a small Seax, there isn't a lot in this billet. Some of this steel turned up in Scandinavia around 900 AD. It was used to create a sword known as the ULFBERT swords. A sword with steel 1000 years ahead of anything in Europe. The current theory is that the Vikings made it far enough to trade for some of this steel.

This stuff is bouncing my hammer off of it. It is the hardest steel I've worked yet.

Re: Recent projects

Posted: Tue Feb 20, 2024 12:45 am

by Animal

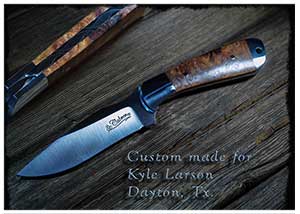

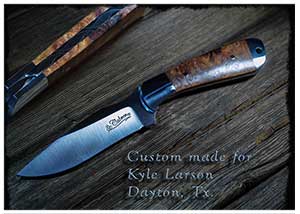

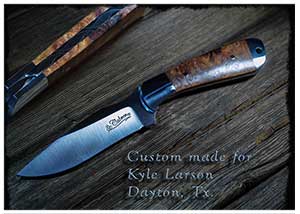

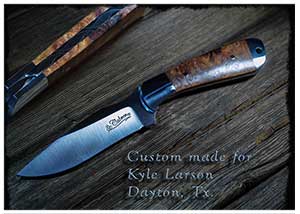

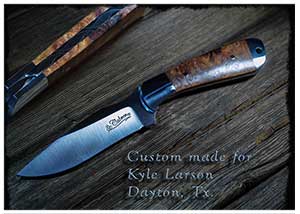

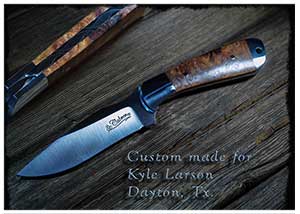

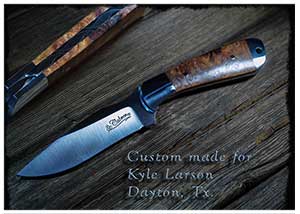

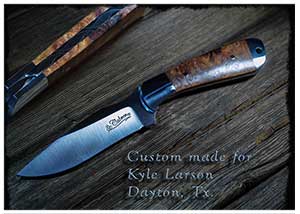

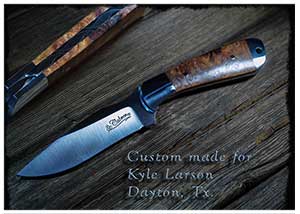

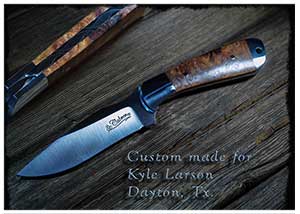

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

Re: Recent projects

Posted: Tue Feb 20, 2024 12:27 pm

by Blast

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

That's a nice knife.. i know he was getting out of it a couple years ago when I made a knife and sent it to him to finish. Any word on how he's doing?

Re: Recent projects

Posted: Tue Feb 20, 2024 1:43 pm

by Animal

Blast wrote: ↑Tue Feb 20, 2024 12:27 pm

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

That's a nice knife.. i know he was getting out of it a couple years ago when I made a knife and sent it to him to finish. Any word on how he's doing?

nope.

Re: Recent projects

Posted: Tue Feb 20, 2024 2:58 pm

by Ricrude

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

He had amazing products...

Re: Recent projects

Posted: Wed Feb 21, 2024 4:28 am

by Blast

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

Re: Recent projects

Posted: Wed Feb 21, 2024 1:55 pm

by Animal

Blast wrote: ↑Wed Feb 21, 2024 4:28 am

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

thats why you need one of those power hammers.

Re: Recent projects

Posted: Wed Feb 21, 2024 9:49 pm

by Blast

Animal wrote: ↑Wed Feb 21, 2024 1:55 pm

Blast wrote: ↑Wed Feb 21, 2024 4:28 am

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

thats why you need one of those power hammers.

Not gonna argue. It would make production runs on stuff easier.

Re: Recent projects

Posted: Wed Feb 21, 2024 9:51 pm

by Animal

Blast wrote: ↑Wed Feb 21, 2024 9:49 pm

Animal wrote: ↑Wed Feb 21, 2024 1:55 pm

Blast wrote: ↑Wed Feb 21, 2024 4:28 am

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

thats why you need one of those power hammers.

Not gonna argue. It would make production runs on stuff easier.

I watched a short youtube of a guy working that wootz steel. his hand held hammer was bouncing off of it like a golf ball. But those power hammers were working it fine.

Re: Recent projects

Posted: Thu Feb 22, 2024 12:19 pm

by Blast

Animal wrote: ↑Wed Feb 21, 2024 9:51 pm

Blast wrote: ↑Wed Feb 21, 2024 9:49 pm

Animal wrote: ↑Wed Feb 21, 2024 1:55 pm

Blast wrote: ↑Wed Feb 21, 2024 4:28 am

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

Animal wrote: ↑Tue Feb 20, 2024 12:45 am

i'm not sure if DiverTexas changed the name of his knife making business or sold it, but I have one of his hunting knives and its the best knife I have ever had. And I have (and have had) so many different hunting knives I lost count. Its just a basic shape, but its just perfect. And its on the minimal amount of steel required. Mine only has a 4 inch blade. It looks similar to this:

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

thats why you need one of those power hammers.

Not gonna argue. It would make production runs on stuff easier.

I watched a short youtube of a guy working that wootz steel. his hand held hammer was bouncing off of it like a golf ball. But those power hammers were working it fine.

That was my finding too. My hammer was bouncing off until I started getting it flat enough to use the diagnal peen on my hammer and the offset hammer blows on the face of the anvil or the horn of the anvil. I'll be working on it a but more on Saturday and maybe be able to figure out the heat treatment

Re: Recent projects

Posted: Thu Feb 22, 2024 1:17 pm

by stonedmegman

Blast wrote: ↑Thu Feb 22, 2024 12:19 pm

Animal wrote: ↑Wed Feb 21, 2024 9:51 pm

Blast wrote: ↑Wed Feb 21, 2024 9:49 pm

Animal wrote: ↑Wed Feb 21, 2024 1:55 pm

Blast wrote: ↑Wed Feb 21, 2024 4:28 am

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

thats why you need one of those power hammers.

Not gonna argue. It would make production runs on stuff easier.

I watched a short youtube of a guy working that wootz steel. his hand held hammer was bouncing off of it like a golf ball. But those power hammers were working it fine.

That was my finding too. My hammer was bouncing off until I started getting it flat enough to use the diagnal peen on my hammer and the offset hammer blows on the face of the anvil or the horn of the anvil. I'll be working on it a but more on Saturday and maybe be able to figure out the heat treatment

After all that pounding you better be careful whacking off or you're bound to do some serious damage.

Re: Recent projects

Posted: Thu Feb 22, 2024 2:01 pm

by Animal

Blast wrote: ↑Thu Feb 22, 2024 12:19 pm

Animal wrote: ↑Wed Feb 21, 2024 9:51 pm

Blast wrote: ↑Wed Feb 21, 2024 9:49 pm

Animal wrote: ↑Wed Feb 21, 2024 1:55 pm

Blast wrote: ↑Wed Feb 21, 2024 4:28 am

Ricrude wrote: ↑Tue Feb 20, 2024 2:58 pm

He had amazing products...

The handles can take forever. I like keeping it simple. Just handled a little skinner with maple today. Sanded to 220 and put boiled linseed oil on.

That wootz steel is being difficult. It took me several hours yesterday and today to finally work it down to the thickness I wanted.

thats why you need one of those power hammers.

Not gonna argue. It would make production runs on stuff easier.

I watched a short youtube of a guy working that wootz steel. his hand held hammer was bouncing off of it like a golf ball. But those power hammers were working it fine.

That was my finding too. My hammer was bouncing off until I started getting it flat enough to use the diagnal peen on my hammer and the offset hammer blows on the face of the anvil or the horn of the anvil. I'll be working on it a but more on Saturday and maybe be able to figure out the heat treatment

in the videos, even with the guys working it with hammers, it did seem to start to soften up the more they worked it. maybe they just figured out how to adjust their attack. But it looked kind of like taffy, the more it was worked the more easy it was to work it. if that makes sense.

Re: Recent projects

Posted: Thu Feb 22, 2024 3:17 pm

by Blast

So when your hitting the steel, you're trying to get the steel to move through the whole piece. Working with a 2 to 4 pound hand hammer isn't going to get the impact that you want when you are working thicker and wider pieces. That's what causes the fishmouth. I'll get in the shop tomorrow night and get pictures of the steel like this. Once it gets thinner the heat and force of impact transfers better and allows the steel to move faster and more evenly. It is in a semi plastic state when it's that hot, so taffy is a fair description but playdough is more of an equivalent and bwe actually recommend people who want to get started but don't have a place use that and a rawhide hammer to start learning how the steel moves when hit.

Re: Recent projects

Posted: Mon Apr 01, 2024 7:12 pm

by Homebrew

Here's another idea for you.

Re: Recent projects

Posted: Mon Apr 01, 2024 7:34 pm

by Animal

it seems like a better design would have been to have that lower part of the blade curve back to touch the handle so there was no spring in the blade.

Re: Recent projects

Posted: Mon Apr 01, 2024 7:37 pm

by rule34

Some things are never meant to be used, just wall hangers.

Re: Recent projects

Posted: Mon Apr 01, 2024 7:50 pm

by Animal

rule34 wrote: ↑Mon Apr 01, 2024 7:37 pm

Some things are never meant to be used, just wall hangers.

like Kate Beckinsale

Re: Recent projects

Posted: Mon Apr 01, 2024 7:53 pm

by rule34

Animal wrote: ↑Mon Apr 01, 2024 7:50 pm

rule34 wrote: ↑Mon Apr 01, 2024 7:37 pm

Some things are never meant to be used, just wall hangers.

like Kate Beckinsale

Oh trust me, she would get used.

Re: Recent projects

Posted: Tue Apr 02, 2024 11:27 am

by disco.moon

I picked up this free 1976 Barbie star traveler RV. The boyfriend disassembled it and I used a heat gun to remove the old stickers. I was able to salvage a few good ones. Next is to paint it a flat black and come up with a cool design. I have an old Barbie that I call "Fish-n-Chips"; she's an old Irish Barbie that was gifted to me last year by my friend who resells all the toys.

Barbie Star Traveler

Re: Recent projects

Posted: Tue Apr 02, 2024 11:43 am

by stonedmegman

Without a roof you'll need a crossbar to hold the stipper pole.

Re: Recent projects

Posted: Tue Apr 02, 2024 12:07 pm

by Ricrude

stonedmegman wrote: ↑Tue Apr 02, 2024 11:43 am

Without a roof you'll need a crossbar to hold the stipper pole.

I thought the exact same thing...